By Hannah Wiedner

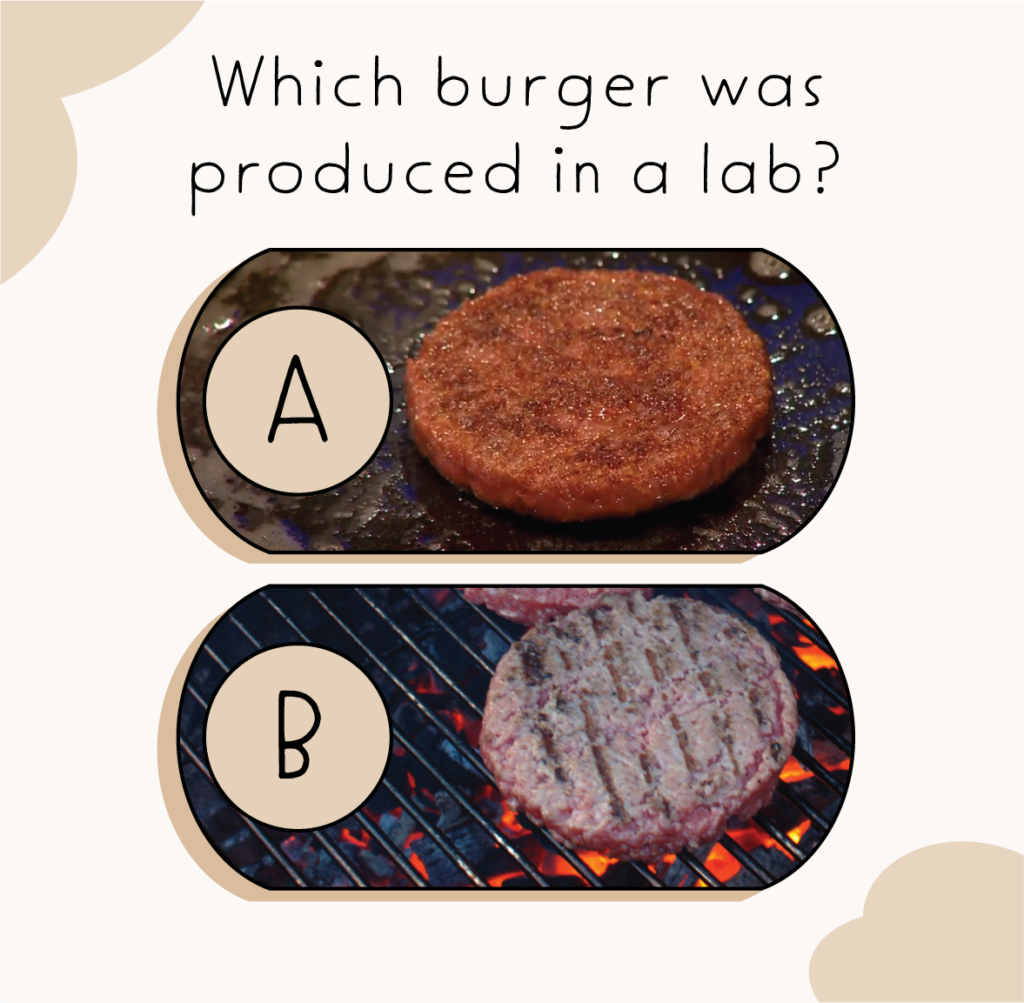

Take a close look at the burger patties below. One of them was created through conventional agriculture methods. The other is lab-grown (also known as cell-cultured meat or cultivated meat). Can you tell which is which?

Would it surprise you to learn that Patty A was created in a laboratory? In 2013, Patty A was the first publicly-revealed cultivated meat product: a burger which cost a whopping $330,000 to produce.

How is meat grown in a laboratory? In general, the process begins with the isolation of immature muscle cells from an animal (typically a cow, pig, chicken, or fish). These precious cells are cataloged, tested, and then frozen to establish a collection of cell lines for later use.

To create meat, the animal cells are fed a nutritious mix of proteins, sugars, growth factors, and fats (collectively known as “growth medium”) inside a chamber called a “bioreactor”. A bioreactor allows scientists to tightly control the temperature, pH level, and oxygen supply that cells are exposed to. The precise regulation of these environmental conditions is essential for encouraging cells to grow outside of the body! (Check out more about how scientists grow cells for biomedical research from the NC DNA Day Blog here)

After growing up a hearty supply of cells, it’s time to start forming muscle-like tissue. By changing the composition of the medium fed to the cells, scientists can cause individual cells to fuse and form structures that resemble smaller parts of a muscle called “muscle fibers.”

In some cases, “scaffolding” is added to help the cells more closely mimic conventional meat. Like scaffolding on the outside of a building construction, these structures provide a framework that the cells can cling to as they grow and divide. Scaffolding is made out of a variety of edible materials including gelatin (what Jell-O is made of) and alginate (naturally found in algae).

Finally, the meat can be harvested and prepared to eat!

Why make cultivated meat? These revolutionary methods could be harnessed to increase food security and sustainability in meat production. In some cases, cells can be collected through a muscle biopsy, without harm to the donor animal. Establishing donor cell lines with a high (or infinite) replication capacity could provide a virtually limitless supply of meat. Switching from conventional to cultivated meat practices could greatly reduce the need to source meat from animals. It should be noted that the production of some cultivated meats still rely on animal products, particularly in the growth medium. Alternatives derived from plants have been developed, and are necessary to fully eliminate dependance on animals for meat production.

Removing the need to sustain large livestock herds could have ecological and environmental benefits. For example, cultivated salmon could reduce the environmental pressures of overfishing on natural fish stocks. In 2019, 35% of marine stocks were fished at unsustainable levels according to the Food and Agriculture Organization of the United Nations. Cultivated salmon meat may reduce the need for wild-caught or farmed fish and allow fish populations to recover.

Other benefits of adopting cultivated meat include the reduced use of antibiotics (since there aren’t concerns from livestock getting sick) as well as preventing food-borne/zoonotic illnesses that currently plague conventional meat production. Scientists are also examining ways to create more nutrient-dense meat products that have the potential to be healthier than those currently available.

How does cultivated meat differ from meat alternatives like Impossible Burgers? Many meat alternatives like the Impossible Burger get their protein by extracting it from plants!

For example, Impossible Burgers are made by combining soy or potato protein with added vitamins, amino acids, sugars, fats, heme, and a binding agent. All of these add-ins help to replicate the consistency and flavor of meat. One promise of cultivated meat is the potential to more closely mimic the experience of consuming traditional meat. Besides the sensory experience, there are nutritional, economic, and environmental differences between plant-based and cultivated meat that should be taken into account.

Where can I buy cultivated meat? It’s not in stores just yet! Scaling up meat production has been a major challenge for the industry, as has been keeping up with the low cost of conventional meat. Cultivated meat prices have significantly dropped since the $330,000 burger to estimates as low as $10 per patty; however, this is still about ten times more expensive than traditional beef.

Costly equipment, cells, and growth medium currently limit the ability for cultivated meat to compete with conventional meat. Many are optimistic that these costs can be overcome as technology improves to grow and process cells. This is particularly vital because encouraging consumers to switch from conventional to cultivated meat will likely require cultivated meat to become a more cost-effective option.

Another limiting factor is regulatory approval required by the Food and Drug Administration (FDA). In November 2022, the FDA completed the first pre-market evaluation of a cultivated meat product – a chicken breast created by UPSIDE Foods. In essence, the FDA gave UPSIDE Foods the green light on their production process, which could pave the way for future approvals of cultivated meat. So, cultivated meat isn’t widely available yet, but may be on your shelves in the coming years!

What do you think? Would you become a steak-holder in the cultivated meat industry?